Like a shadow that lingers at the edge of a window, condensation on walls often points to underlying issues. You’ll want to know what anti-condensation paint can—and can’t—do, how humidity and temperature interact, and when a coating is truly a help versus a Band-Aid. It may delay dampness on cold, poorly insulated surfaces, but it won’t fix leaks or ventilation gaps. Keep an eye on monitoring results and broader moisture controls as you weigh your options.

How Condensation Forms on Walls

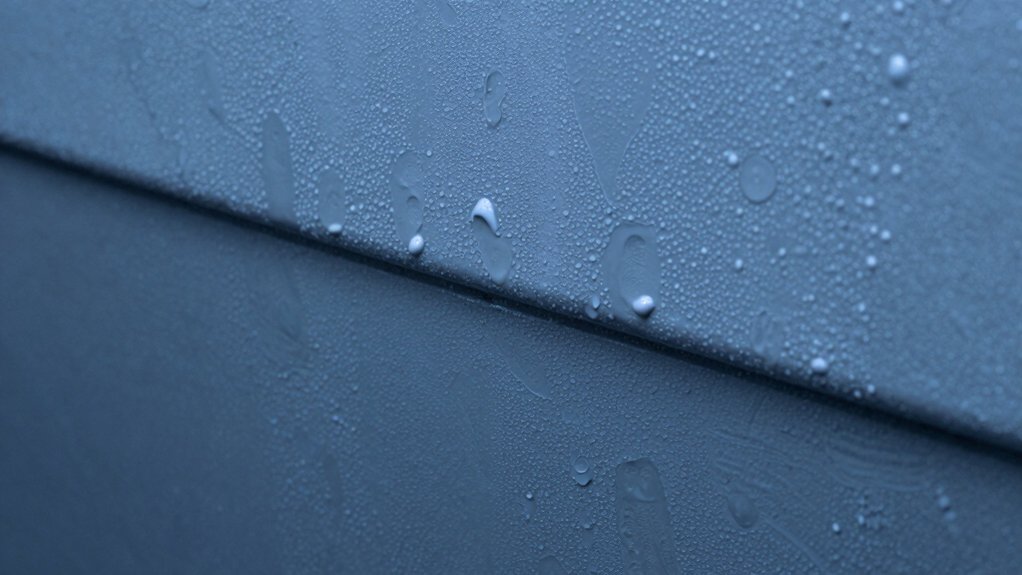

Condensation on walls occurs when warm, moist indoor air meets cooler surfaces. You can picture it as tiny droplets forming where temperature difference is greatest, usually near windows, exterior walls, or areas with poor insulation.

Humidity from cooking, showering, drying laundry, or breathing adds moisture to the air. If the wall surface is cooler than the surrounding air, the water vapor condenses on the surface rather than staying dissolved.

Over time, repeated cycles dampen plaster or paint and can promote mold growth. Relative humidity above about 60% increases condensation risk, especially in winter when indoor air is heated and outer walls stay cold.

Ventilation, insulation, and moisture control measures reduce condensation likelihood, supporting steadier indoor conditions and protecting wall materials.

What Anti-Condensation Paint Is Supposed to Do

You’ll learn how anti-condensation paint works to reduce surface moisture and slow fogging, with a focus on the science behind moisture control, not just marketing claims.

I’ll cover practical application tips to maximize performance, plus common limitations and when to use it alongside proper ventilation and insulation.

This will set the stage for comparing how it behaves in real spaces, how to apply it correctly, and what to expect in different conditions.

How It Works

Anti-condensation paint is designed to manage moisture on surfaces by reducing temperature differentials and promoting a more even surface temperature. You’ll find it works by improving thermal inertia, which slows rapid surface cooling that causes dew.

This can help suppress condensation formation on walls or ceilings in typical indoor conditions. The active ingredients are often micro-encapsulated compounds or additives that alter heat transfer characteristics or slightly raise surface temperature when exposed to ambient warmth.

In controlled testing, coatings with appropriate binder systems maintain surface temperatures closer to room temperature, reducing the likelihood of dew points forming.

Real-world results vary with climate, substrate, and exposure, so evaluations should consider ventilation, humidity, and consistent application. Overall, evidence supports modest condensation reduction under suitable circumstances.

Application Tips

To get the most from anti-condensation paint, start with proper surface preparation and consistent application.

Before you apply, clean and dry the area, remove loose material, and fix any leaks or moisture sources.

Follow manufacturer guidelines for compatible primers and topcoats to ensure adhesion and durability.

Apply in thin, even finishes rather than thick coats, and maintain a steady technique across the surface to prevent streaks or pooling.

Temperature and humidity matter: work within recommended ranges, and allow adequate drying times between coats.

Use a suitable applicator, such as a roller or brush, and avoid overworking the paint, which can trap air.

Inspect the completed work under normal conditions and recoat only if the surface remains uniformly dry and free of defects.

Limitations & Use

While anti-condensation paint is designed to reduce surface moisture and deter condensation buildup, it isn’t a universal solution for every humidity issue.

In practice, it works best when applied to surfaces prone to rapid temperature changes, such as exterior walls, kitchens, or bathrooms, where moisture risk is recurrent.

You shouldn’t expect it to fix chronic leaks, poor ventilation, or high ambient humidity on its own.

Performance depends on proper surface preparation, correct layer thickness, and choosing a product suited to your climate.

Results may vary with substrate, cement-based plasters, or old paints.

Follow manufacturer guidelines, allow full cure, and pair with ventilation improvements and dehumidification when needed.

Consider cost, durability, and maintenance to determine if it aligns with your moisture management plan.

The Science Behind Humidity and Temperature

Humidity and temperature interact to drive condensation: when warm, moist air contacts a cooler surface, the air can’t hold as much moisture and droplets form. You’ll notice this most on windows, walls, and appliances in damp rooms.

The science is straightforward: relative humidity measures how much moisture the air contains compared to its capacity. When surface temperatures drop below the dew point, water condenses.

Temperature differences, air movement, and humidity levels all influence how quickly this occurs. In practical terms, raising surface temperatures, reducing ambient humidity, or improving airflow can reduce condensation risk.

Ventilation, insulation, and moisture control matter as much as coatings. Anti-condensation paints work best as part of a broader strategy, not as a sole solution.

Real-World Effectiveness: What the Studies Show

Real-world studies show anti-condensation paints can lower surface condensation under certain conditions, but results vary by environment and application.

In controlled trials, you’ll see modest reductions when humidity peaks and surface temperatures approach room temperature, yet performance often drops with higher ambient moisture or rapid temperature swings.

Researchers emphasize material quality, substrate compatibility, and coating thickness as critical factors influencing outcomes.

You should note that effectiveness isn’t universal; some tests report negligible changes on poorly insulated walls or in spaces with intermittent ventilation.

Consumer-relevant findings point to realistic expectations: paints can help minimize frequent fogging and drip formation in consistently heated or climate-controlled areas.

Use these results to assess fit for your space, rather than assuming universal, long-term condensation elimination.

Surface Preparation and Application Tips

Proper surface prep is essential for anti-condensation paints to perform as advertised. Before you apply the coating, clean the surface to remove dust, grease, and old paint flaking away. Lightly abrade glossy areas to improve adhesion, then wipe with a damp cloth and let it dry completely.

Check that the substrate is dry and stable; moisture behind the coating can undermine effectiveness. Follow manufacturer guidance for compatible primers and compatible top coats.

Apply in thin, even coats, maintaining a consistent pace to avoid puddling or misshapen edges. Allow each layer to cure fully according to the label before adding another.

If you’re unsure about moisture or prep steps, perform a small test area and inspect for even coverage and adhesion. This approach supports consistent, evidence-based results.

Ventilation and Moisture Control as Complementary Measures

Ventilation and moisture control work best when paired with proper surface preparation, because even a well-prepped surface can fail if ambient conditions undermine the coating.

You’ll reduce indoor humidity by using exhaust fans during showers, cooking, and laundry, and by running ventilation longer when humidity is high. Pair this with dehumidification in damp spaces to maintain relative humidity below levels that promote condensation.

Ensure air exchange isn’t limited by blocked vents or closed doors, which can create stagnant zones. Temperature plays a role too: keep rooms within a stable range and avoid rapid swings that encourage condensation on cool surfaces.

Combine these practices with consistent cleaning and routine inspection for damp patches, so anti-condensation coatings perform as designed and stay effective over time.

Common Misconceptions About Anti-Condensation Paint

Common misconceptions about anti-condensation paint can blur what actually works. You’ll find that efficacy isn’t magical, but based on proper product selection, surface prep, and realistic expectations about temperature and humidity.

It’s also important to separate myths about temperature versus humidity and to follow proven prep steps rather than rely on slogans.

Misbeliefs About Efficacy

Many people assume anti-condensation paints instantly prevent moisture buildup, but their efficacy depends on broader conditions. You’ll need to view these products as part of a broader moisture-management strategy, not a magic fix.

In reality, paints can delay condensation only if surface temperature and humidity levels cooperate over time. Most anti-condensation formulas work by improving surface heat retention or promoting subtle moisture handling, yet they don’t alter airflow, seal leaks, or lower room humidity.

Independent tests show variable results across settings, with performance tied to substrate, paint type, and application thickness. When considering a purchase, compare claims to independent data, look for certifications, and be wary of promises that ignore ventilation, insulation, or climate.

Use them as a component, not a substitute, for moisture control.

Temperature Vs Humidity Roles

Temperature and humidity play distinct, interdependent roles in condensation, but misconceptions persist about how anti-condensation paints influence them. You’ll find that temperature governs water vapor’s capacity to stay airborne, while humidity reflects how much moisture is present.

Anti-condensation paints don’t raise room temperatures; they manage surface conditions to minimize condensation risk. In practice, lowering relative humidity or improving ventilation reduces moisture availability, addressing the root cause rather than masking symptoms.

Paints can create a more favorable microclimate on surfaces, delaying droplet formation when humidity is high, but they don’t eliminate the need for moisture control. For effective results, combine proper ventilation, sensible humidity levels, and appropriate coating selection, following manufacturer guidelines and local building conditions.

Evidence supports targeted humidity management alongside suitable products.

Surface Prep Myths

Surface prep myths surround anti-condensation paints, and clear guidance helps you separate fact from fiction. You might hear that elaborate sanding or priming guarantees results, but evidence shows prep quality matters, not ritual steps. Clean, dry surfaces free of dirt, oils, and moisture are essential; otherwise, coatings can fail or trap moisture.

Don’t assume old, flaky paint must be removed completely—feasible feathering and light scuffing often suffice for adhesion, depending on the substrate. Follow manufacturer instructions for compatible primers and systems, and respect cure times.

Misconceptions about sealing drafts or removing humidity with paint are unsupported; condensation control relies on film properties and surface temperature, not magical coatings. Evaluate products based on tested performance, warranties, and real-world demonstrations rather than anecdotes.

When to Use It and When to Seek Alternatives

Condensation can be a problem on poorly insulated surfaces or in environments with high humidity, so use anti-condensation paint when rapid moisture buildup is common and traditional coatings fail to prevent droplets.

You should consider this option if you regularly observe mist or droplets forming at lower temperatures, or if you live in a damp climate with fluctuating humidity.

Assess the surface type and its exposure: indoor walls, ceilings, or unventilated spaces are higher risk than well-ventilated, heated areas.

Evidence shows that some products improve appearance and reduce moisture film, but results vary by substrate and climate.

Seek alternatives when moisture persists despite proper surface prep, ventilation upgrades, or humidity control, or if you need long-term durability beyond decor.

Compare product specifications, warranties, and independent test data before choosing.

Practical Maintenance and Monitoring After Application

After you’ve applied anti-condensation paint, establish a simple monitoring routine to verify it’s performing as expected and to catch issues early. Regularly inspect painted surfaces for persistent damp spots, peeling edges, or drying delays after shifts in temperature or humidity.

Keep a humidity log and note conditions that precede condensation events. If you see recurrent moisture, re-clean the area, ensure proper ventilation, and confirm the paint’s coverage and compatibility with underlying materials. Avoid overloading with cleaners that could degrade the film.

Compare performance across seasons to detect gaps in protection. Document maintenance steps and timing, so you can distinguish temporary fluctuations from system failures. Rely on manufacturer guidelines for reapplication intervals and defect reporting to support long-term effectiveness.

Frequently Asked Questions

Can Anti-Condensation Paint Prevent Mold Growth Long-Term?

Anti-condensation paint can reduce surface moisture, but it won’t guarantee long-term mold prevention. You’ll likely see fewer condensation events, yet mold depends on humidity and cleanliness; controls like ventilation and moisture reduction are essential for lasting results.

Does Paint Thickness Affect Condensation Reduction Effectiveness?

Paint thickness can affect condensation reduction; thicker coats may improve moisture resistance but can trap air and crack, reducing effectiveness. You should follow manufacturer guidelines, guarantee proper surface prep, and consider insulation and ventilation for best, evidence-based results.

Is There a Warranty on Performance for Different Surfaces?

Yes, warranties vary by product and surface; always check the label and manufacturer terms. You’ll typically find performance coverage for specific substrates, environmental conditions, and application guidelines, plus duration and exclusions, so verify compatibility before purchase and use.

How Quickly Does Anti-Condensation Paint Dry and Cure?

You’ll typically see dry-to-touch in 1–4 hours and cure in several days, depending on product and conditions; follow manufacturer specs, maintain ventilation, and avoid moisture exposure until full cure for reliable performance.

Are There Any Health or Safety Concerns During Application?

Yes, there are health and safety concerns during application. Wear PPE, guarantee ventilation, avoid skin and eye contact, follow label directions, keep away from children, and store properly; if symptoms occur, seek medical advice promptly.